VSR DUSTEX®

Dust Suppression and Odour Control

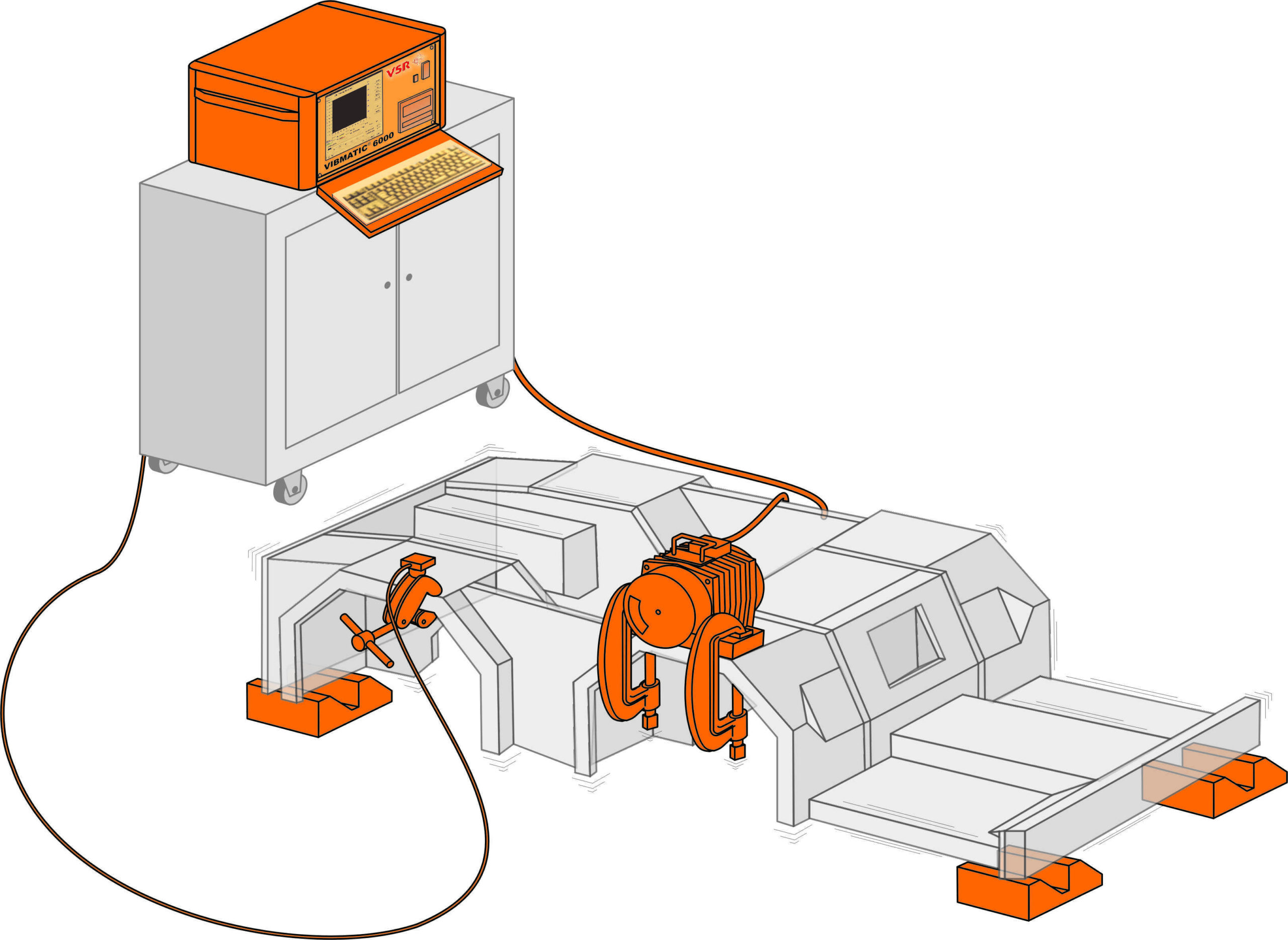

In the sector of dust suppression, we successfully apply our classic spraying systems operating with water or a combination of air and water, dry fog. Our product portfolio also includes mobile dust controllers and our new high-pressure spraying system for industrial dust control.

Sustainable dust control

With water spraying system, water dispersion, high-pressure systems and mobile dust controllers, VSR Industrietechnik GmbH is the first company to offer the entire range of dust binding by using water. The aim of these systems is to protect the environment from harmful components such as dust, odours, viruses and bacteria.

Normal pressure dust suppression

Our DUSTEX® water spraying system works with water and offers a wide range of applications. The DUSTEX® water dispersion system removes dust with an air-water mixture and reaches smaller drops sizes.

High-pressure dust suppression

The high-pressure system for dust minimisation operates at 80 - 160 bar and therefore produces a very fine mist through specially designed nozzles. The droplet spectrum is from 5 - 100 μm, depending on the setting.

Mobile dust suppression

In addition, we can offer a very large and competitive range of mobile dust controllers. The ranges start at 10 m and can be up to 150 m.

Effective dust reduction with water

Dust emissions are generally disturbing and also a health hazard. For this reason, most countries now have legal requirements that stipulate a reduction of dust emissions.

- Amazingly high dust binding efficiency, even in almost unsolvable problem cases

- Durable, universal and easy-to-maintain water spraying system

- Optimal dust control achieved via finest droplet size

Rent or Purchase

The mobile dust binding machines can be purchased or rented. If you decide to rent, we deliver our innovative dust binding machines directly to the desired location and put them into operation.

6 Advantages of DUSTEX® dust seuppression

With DUSTEX® systems, planned and installed by us, you can comply with the legal requirements on dust emissions that are currently applicable. In various projects in which measurements were carried out, dust emissions were reduced by more than 90%. The limit value of 10 mg/m³ air could be safely undercut.

Individual solution

Low energy consumption

Freeze protection

Maintenance friendly

Largest selection

Project experience

We protect the Enviroment and People from dust

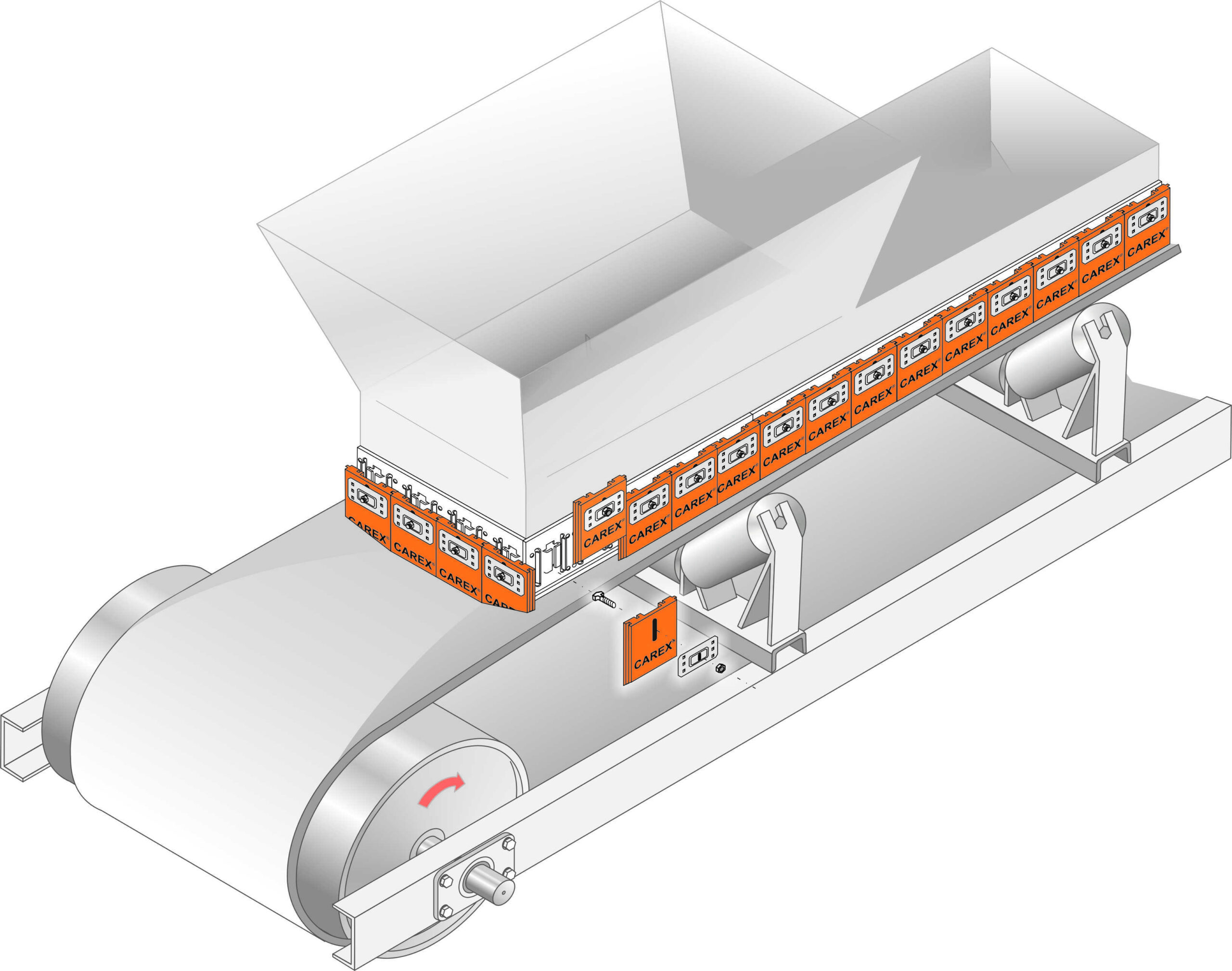

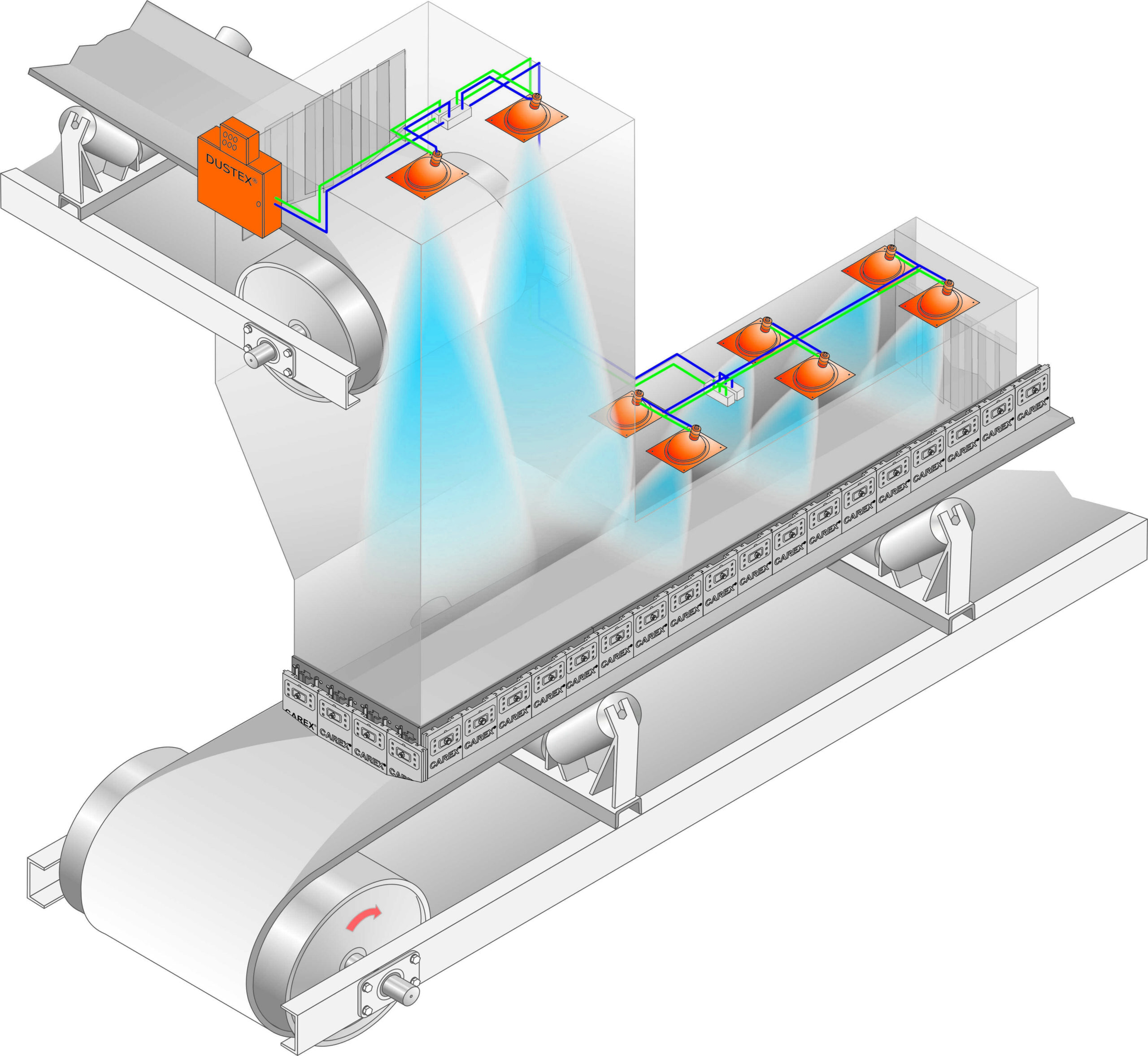

Our tailored solution for dust suppression

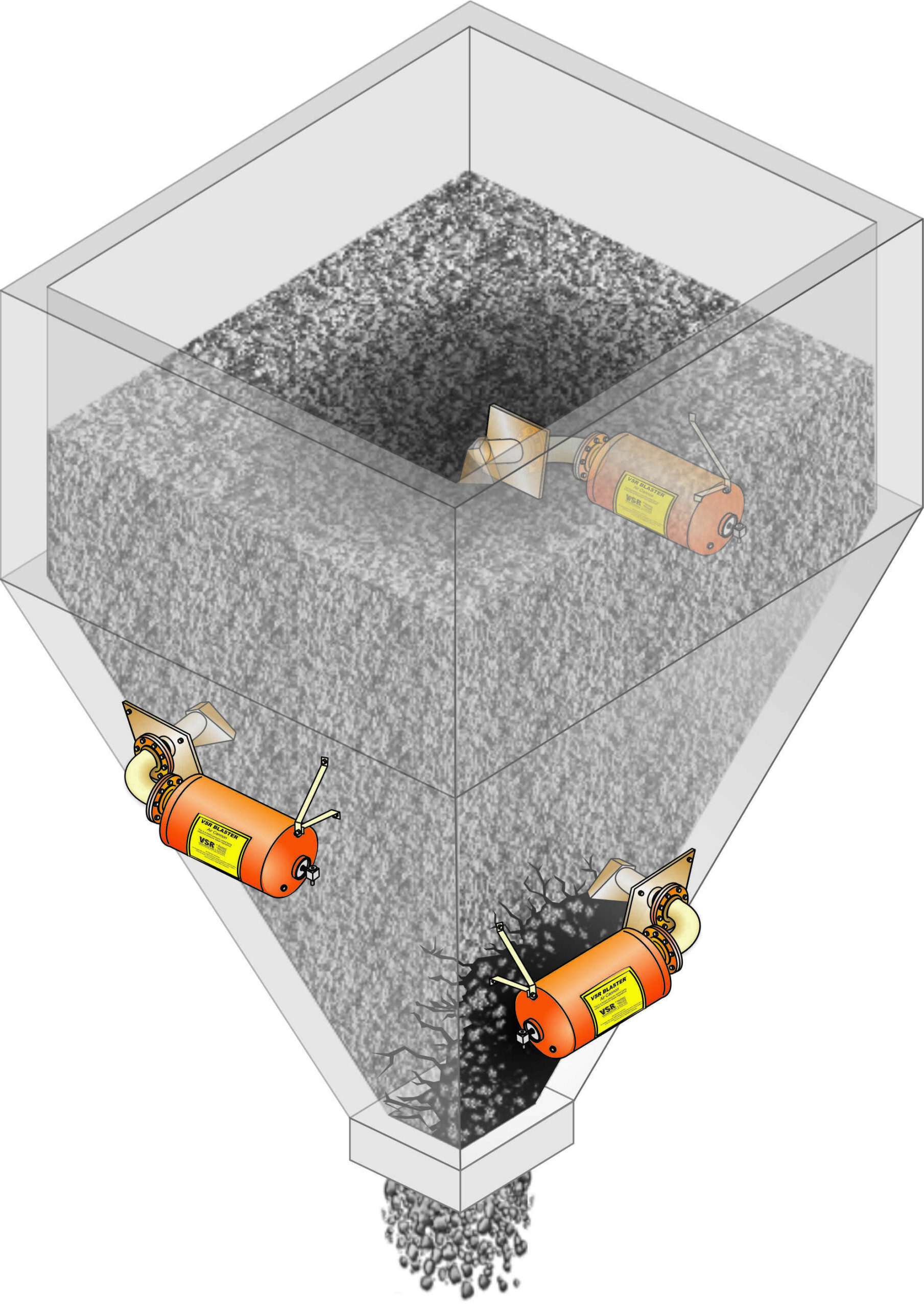

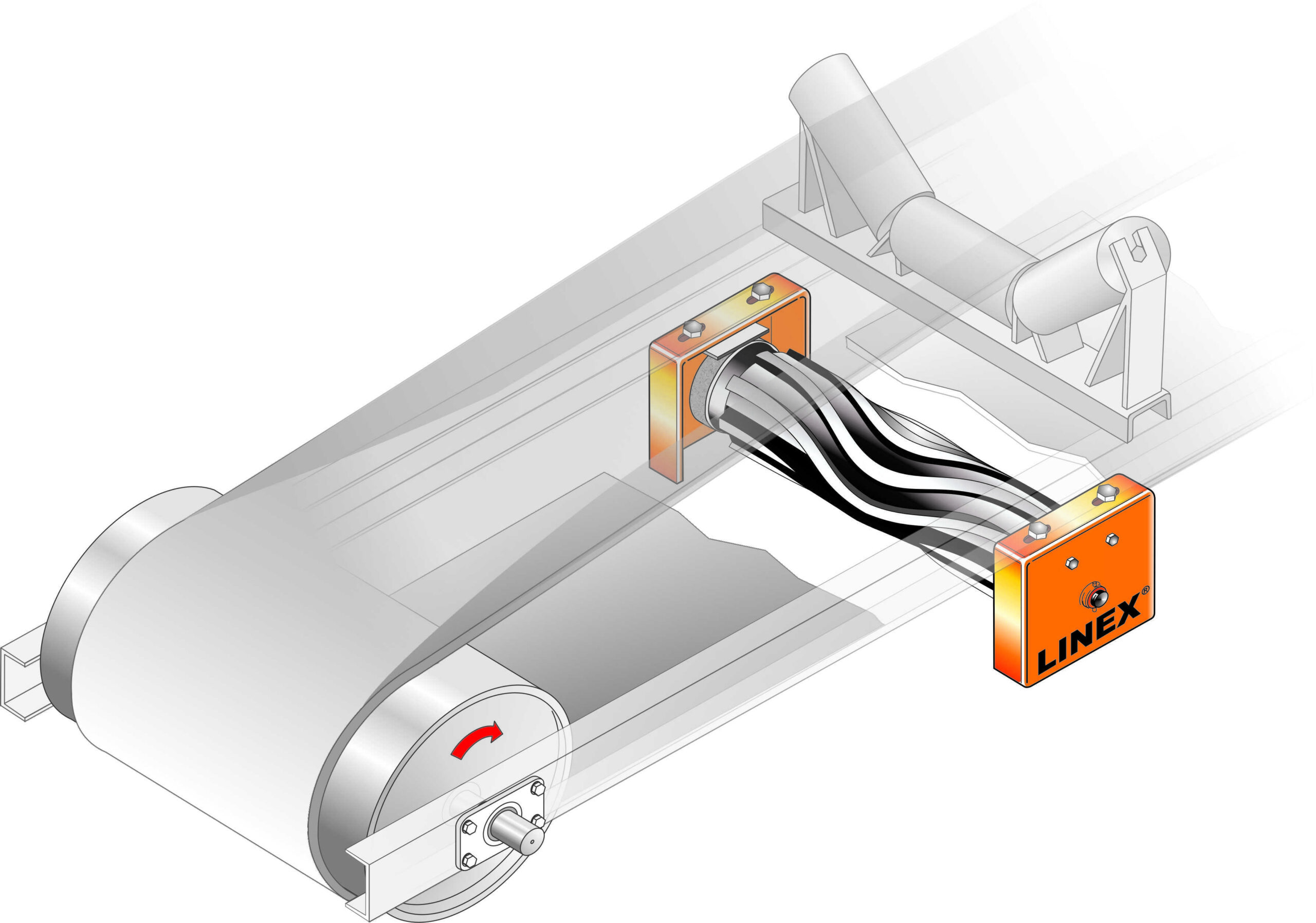

The DUSTEX® water spraying system operates with water. It is used anywhere where outdoor handling situations cannot be enclosed sufficiently and where a slightly higher use of water is not disturbing (or even desired). Due to the large selection of nozzles, an optimal spray pattern can be created for every application. With a working pressure of up to 16 bar, the water will be finely atomised and the droplet spectrum is 50-150 µm.

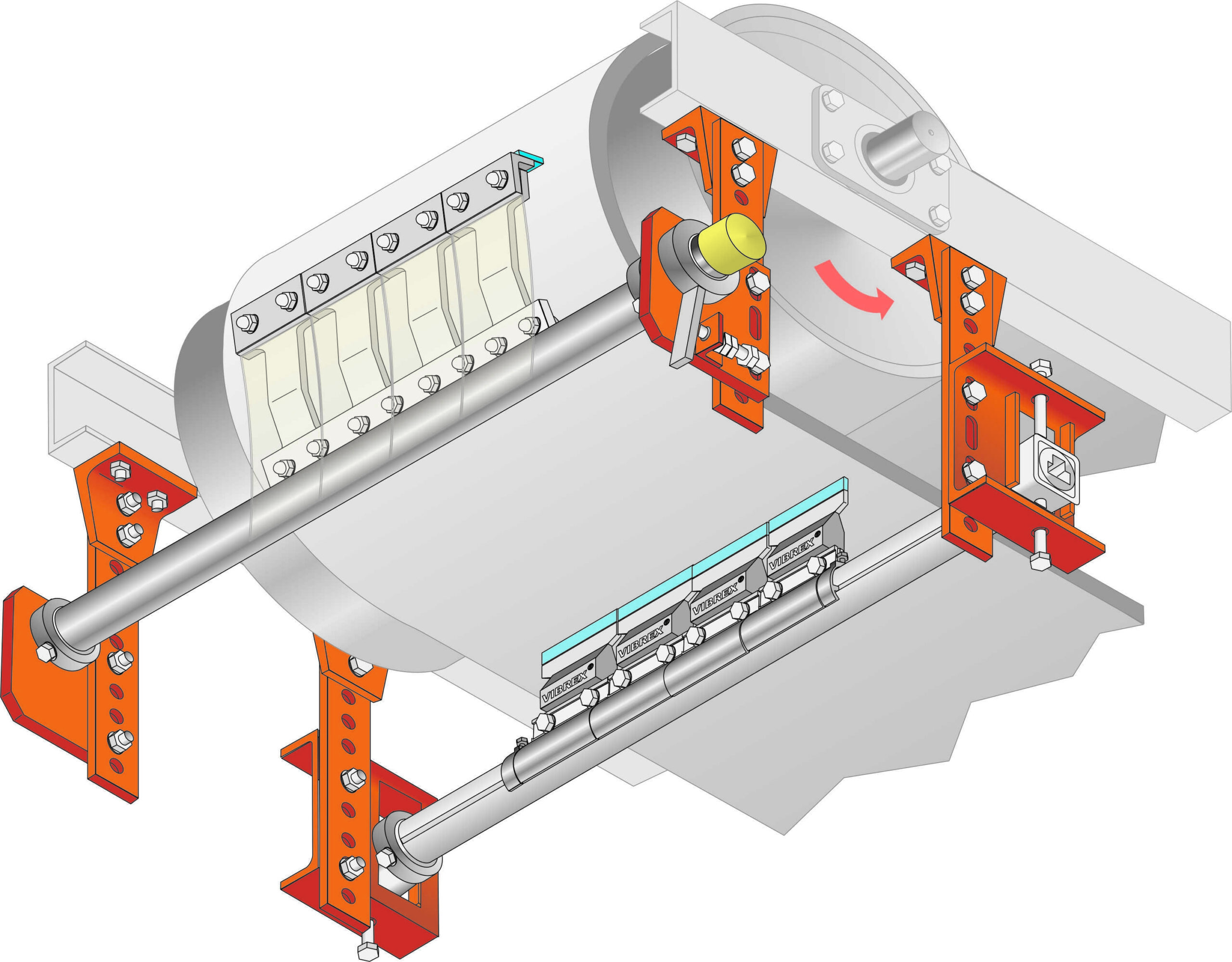

The DUSTEX® dispersion system works with water and compressed air as two-substance spraying. It is recommended to use it whenever the handling dusts are very fine and/or the entry of moisture into the material is to be avoided as much as possible. The droplet spectrum of our self-developed two-substance nozzles is 10-50 µm, also called dry fog, depending on the pressure. With the nozzle types available at VSR, a water flow rate of 10 l/h to 185 l/h per nozzle can be achieved.

The DUSTEX® high-pressure system is used to reduce dust in areas where the dust emission is very high due to handling, transport and processing of dusty goods. In addition to dust suppression, the DUSTEX® high-pressure system can also be used for air humidification, flue gas cooling or odour neutralisation. Water is atomised at high pressure of up to 160 bar through a special nozzle system. The droplet spectrum ranges from 10-100 μm, depending on the setting.

The mobile dust suppression machines are used where adaptation to constantly changing plant conditions is required, when dust needs to be bound in larger areas or when material should be kept moist on changing stockpiles. The mobile machines reaches a throwing distance from 10 m up to 150 m.

Contact us. We look forward to hearing from you!

Aleksander Harasimowicz

+49 2066 996649 • harasimowicz@vsr-industrietechnik.de