VSR LINEX®

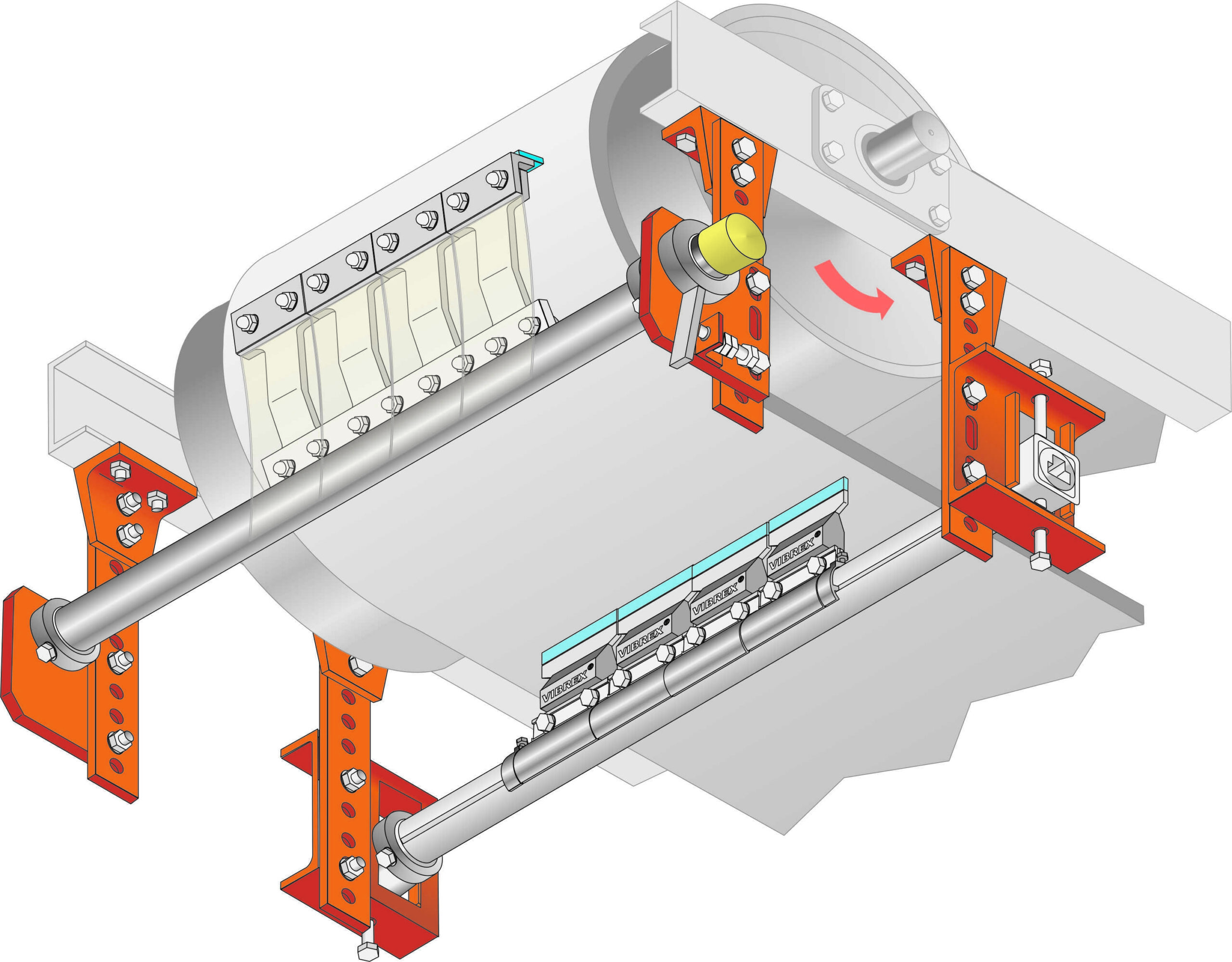

Conveyor belt centring rollers

LINEX® rollers ensure symmetrical belt tracking and protect the belt edges. The conveyor belt belt guidance rollers avoid costly interruptions in operation.

No belt misalignment

With our conveyor belt centring rollers, we prevent belt misalignment.

Advantages

LINEX® conveyor belt centring rollers should not be missing on any conveyor belt, because they correct belt tracking errors due to:

- uneven, worn or incorrectly spliced conveyor belts

- incorrect roller alignment

- conical head drum

- warped steel construction

- one-sided exposure to sunlight

- asymmetrical or transverse thrust loading

- asymmetrical abrasive forces on drums, rollers, scrapers and chute seals.

Specifications

Specification of the LINEX® conveyor belt centering roller:

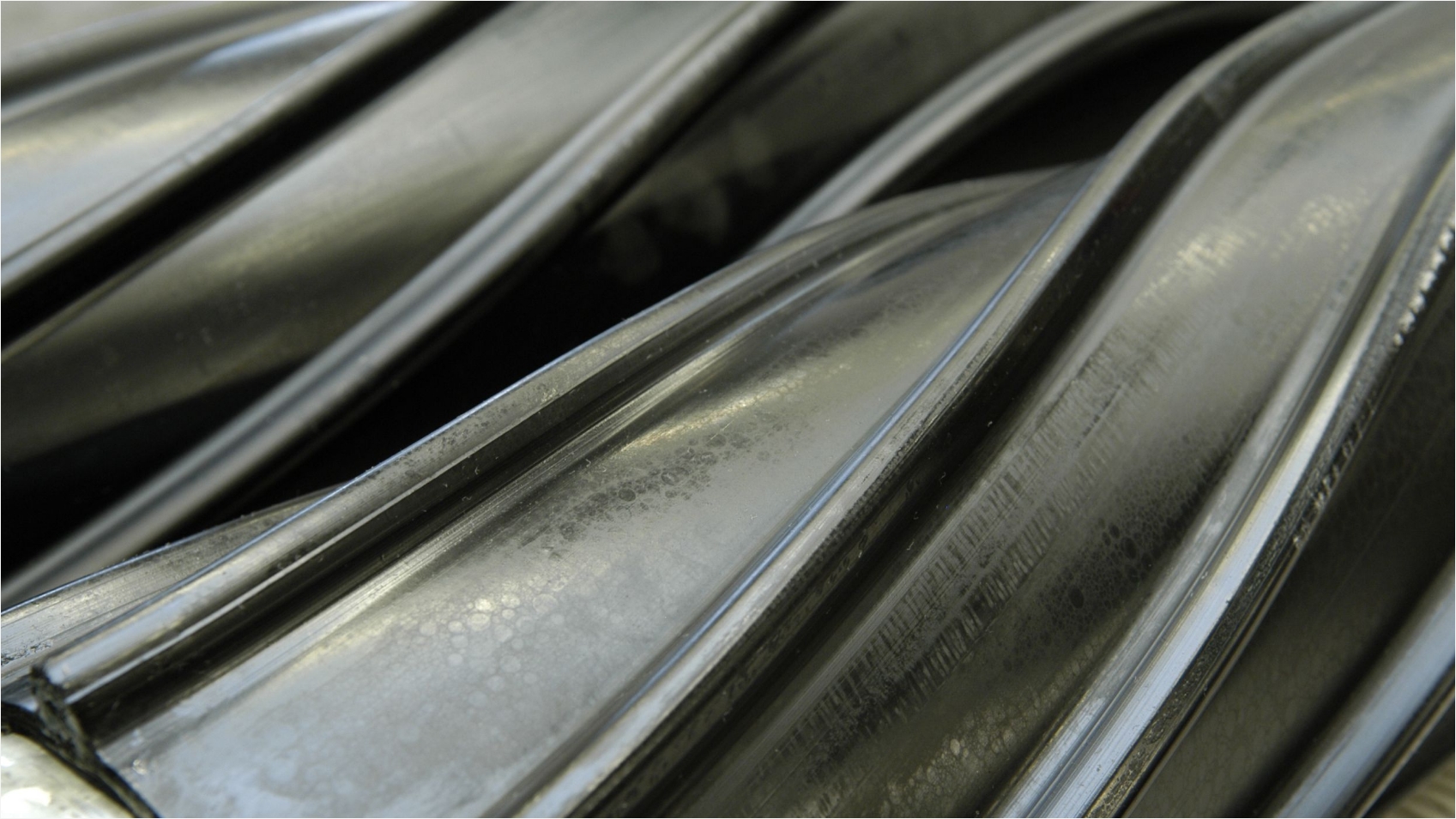

Rubber-coated, with 8 twisted support ribs, brake pads at both ends, tumbling through a double-barrel bearing in the middle on a heavy continuous axle, dust protection sleeves made of cellular rubber, on both sides, 2 galvanized bearing boxes with brake angle and 2 mounting slot holes

Fields of application:

Conveyor belts in lignite and hard coal mining, power stations, cement works, gravel, stone and sand pits, foundries, aluminium smelters, iron and steel works, port handling operations, chemical works, water and sewage works, waste incineration plants and in the wood and metal processing industry.

Avoid conveyor belt misalignment

Designed for optimum belt Guidance

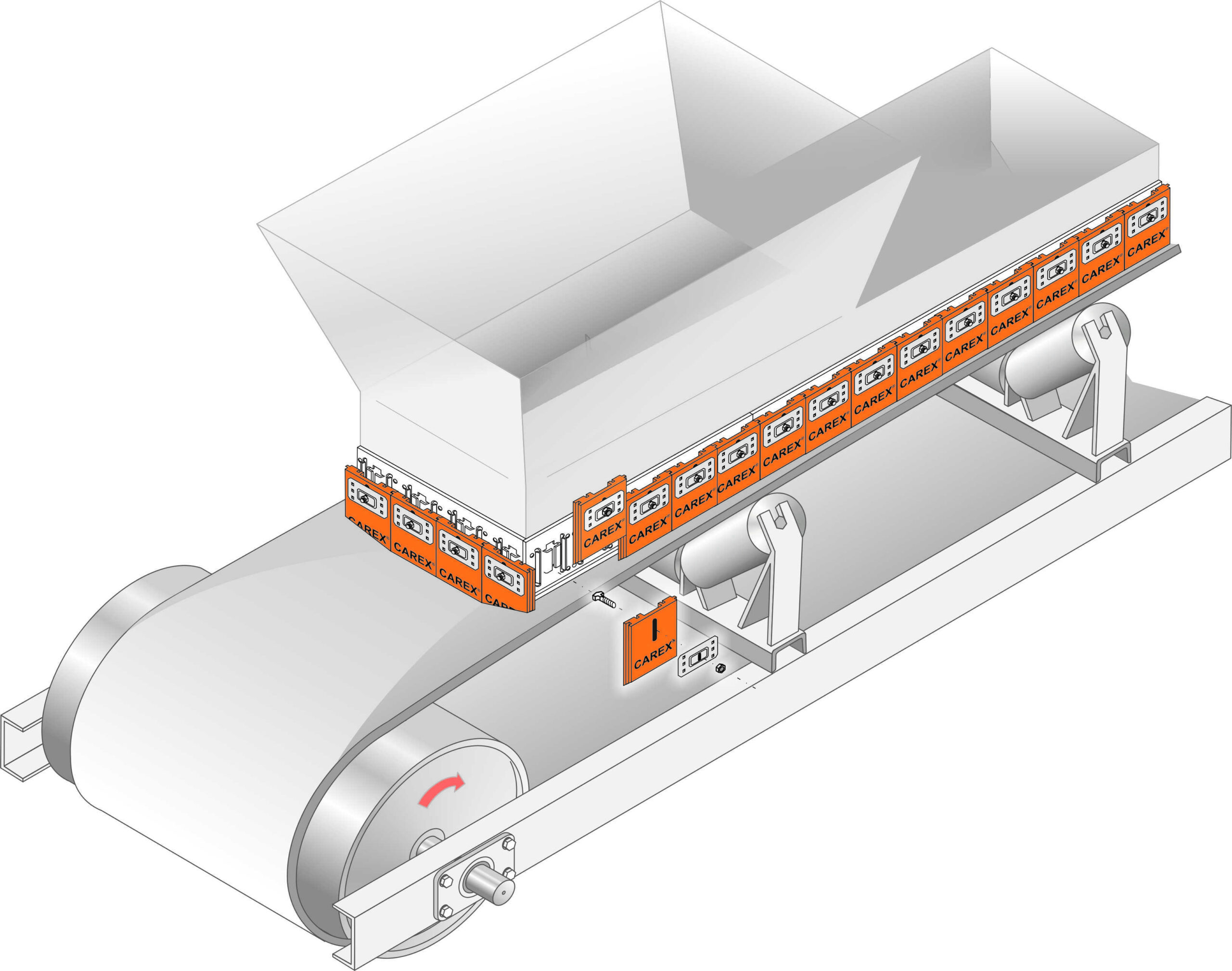

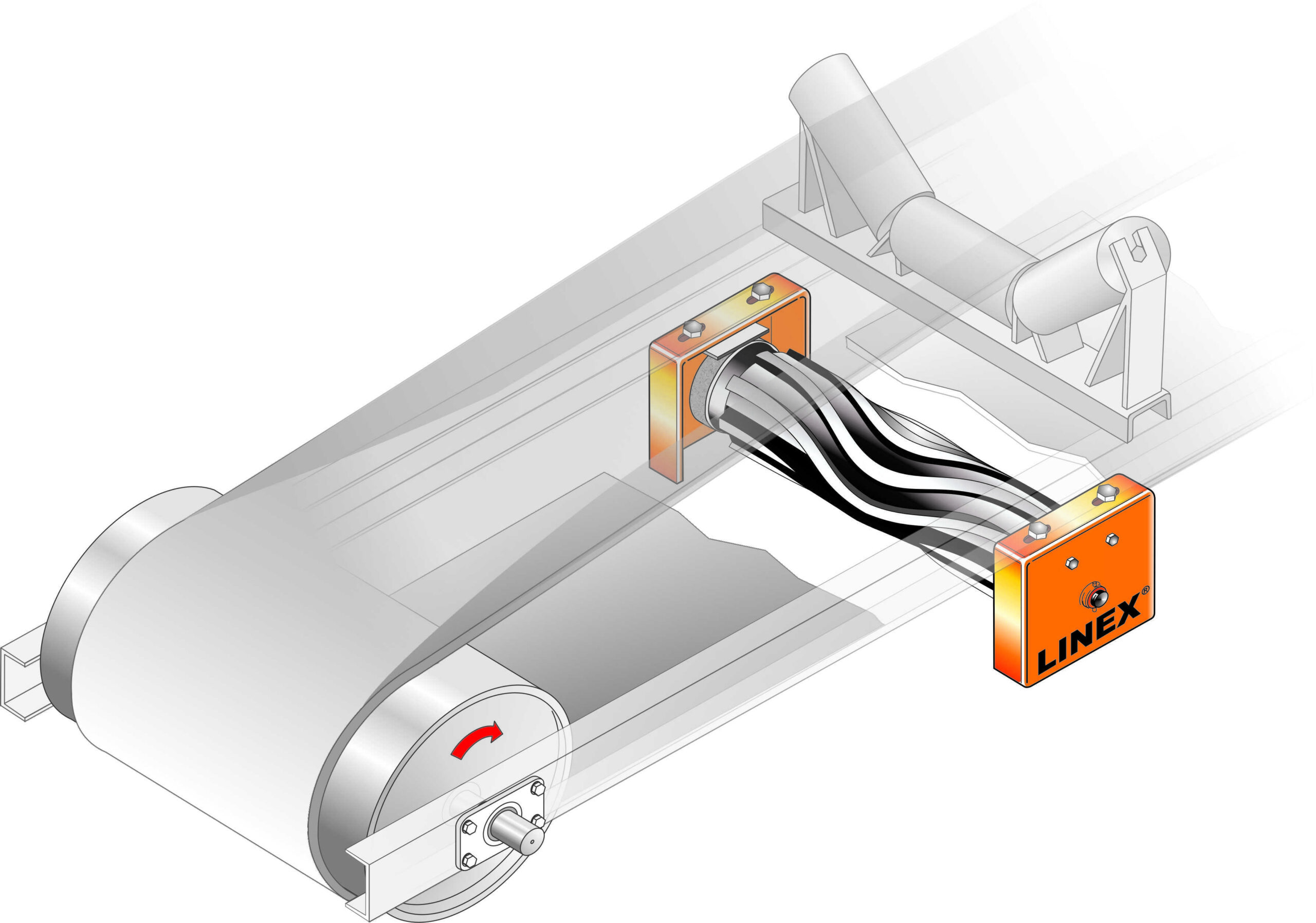

LINEX® conveyor belt centring rollers have been designed according to the physical laws of gravity and friction as well as the knowledge gained from many years of experience with the characteristics of conveyor belts in operation. The LINEX® conveyor belt centring roller ensures the straight running of the conveyor belt. It is installed directly in front of the reversing drum, basically below the material feed hopper, instead of a lower belt idler. In the event of the slightest misalignment, the LINEX® conveyor belt centring roller, which is centrally mounted in the centre of gravity, tilts and twists and guides the belt back to the centre through the frictional effect of its swept rubber ribs. This ensures that the belt is loaded centrally. Lateral overloading and damage to the belt edges or the lateral rubber seals are reliably avoided.

Contact us. We look forward to hearing from you!

Aleksander Harasimowicz

+49 2066 996649 • harasimowicz@vsr-industrietechnik.de